Cambridge City Airport Life Extension Works

CLIENT

Cambridge City Airport is situated close to Cambridge’s historic centre and high-tech business parks and is the ideal gateway to one of the UK’s most famous and thriving cities. Cambridge City Airport is one of the best equipped regional airports in the UK. Offering a full Charter and FBO Service, Hangarage and Parking facilities. It boasts 6000m2+ of modern, flexible hangar space, 10,0002 acres of airfield parking, a 1965-meter runway, and fully operational air traffic control service supported by a full suite of ground services.

CHALLENGE

Marshall Aerospace Group, the Company that owns Cambridge City Airport contracted LAML to undertake various cost-effective life extension works on several Taxiways and the Runway.

Marshall Aerospace Group required maintenance solutions to extend the longevity and serviceable life of these areas for at least a further 5 to 6 years. All activities needed to be minimally disruptive, able to be undertaken out of hours and priority assigned to minimise noise pollution.

ECHO TAXIWAY

Saw cutting and sealing to the Taxiway. The existing aged joint sealant was removed, joints re-cut and new N2 hot applied joint sealant was installed.

Small concrete cracks and concrete bay defects were repaired (rather than full bay replacements being undertaken) using Maxi-Crete. Maxi-Crete is a HAPAS-approved resin-based hot-applied concrete repair system established and approved for use in the airside environment. Maxi-Crete offers life extension to damaged concrete bays/surfaces.

Crack chasing was carried out where required on the taxiway using hot-applied joint sealant. This prevents further deterioration of the concrete by sealing open cracks and preventing further water ingress and FOD creation.

Refreshment of line marking where required in repair locations.

CHARLIE TAXIWAY

The airport wished to extend the life of the asphalt surface on this taxiway, which apart from some areas of fine cracking, was in fairly sound condition.

Rhinophalt, HAPAS-approved, asphalt preservation material was applied to approximately 11,000m2. The application took approximately 4 hours to complete during the day.

Once the Rhinophalt had cured – after about 4 hours, all line marking was reinstated with one pack epoxy paint.

Overbanding was carried out overnight in the same shift on areas of the taxiway where open cracks were visible following the preservation treatment. The overbanding ensures no moisture or water can enter the pavement through the open cracking. Whilst the preservation material will provide some sealing to the surface it does not fill open cracks which is why the overbanding was recommended as an additional treatment, particularly on a more aged surface.

The Taxiway was operational again less than 24 hours after works commencing.

Asphalt preservation works by protecting the asphalt surface from weathering, oxidation, and traffic wear. RHiNOPHALT® protects the existing surface course, specifically the bituminous binder and seals in existing oils and resins whilst at the same improving the binding and waterproofing properties of the surface. One application on older asphalt surfaces can extend pavement life by an additional 3 to 5 years, delaying the massive cost and disruption of a resurfacing intervention.

A RHiNOPHALT® treated surface became more resistant to abrasion, stone loss, and the severe ageing effects of ultra-violet light and water. By minimising the occurrence of cracking, crazing and potholes, RHiNOPHALT® provides significant life extension to the surfacing course, thereby delaying the need for major resurfacing interventions.

RUNWAY, TAXIWAYS ALPHA, BRAVO, CHARLIE, DELTA & RUNWAY HOLDS

Overbanding was carried out to various locations across the Runway, Taxiways and Runway Holds to act as a life extending low cost, quick maintenance solution. Overbanding covers the cracks and provides a repair solution which prevents further water ingress and slows down the process of additional fretting. Cracking results in potential weak points in the surface that allows water or even fuel spillage ingress below the surface and with the changing temperatures and freeze thaw effect can cause further delamination, cracking, and aggregate loss – all of which can cause FOD risks in the airside environment as well as the need for reactive maintenance.

LAML mobilised to assist the airport with undertaking emergency repair works using Maxi-Flex, a polymer modified stress absorbing inlaid repair material, preventing any need to close the runway outside of normal operations.

APRON WORKS

Crack Chasing & Saw Cut & Seal was carried out using N1 hot-applied sealant. Repairs were undertaken to a number of locations on this concrete apron to provide life extension and prevent further degradation to the apron from cracks and defects that had appeared over time.

Maxi-Crete concrete repairs were also carried out on a number of locations at the edges of concrete bays. These repairs will provide service life extension without the need to replace full bays or undertaking more major repair works.

EXPANSION JOINT – DELTA TAXIWAY

An expansion joint needed to be installed on Delta Taxiway with the interface between asphalt and concrete surfacing. The LAML team saw cut to create the joint 25mm wide, 300mm deep, installed filler board, raked out to the required sealant depth(25mm), and then sealed the joint with N1 hot applied joint sealant.

FACTS & FIGURES

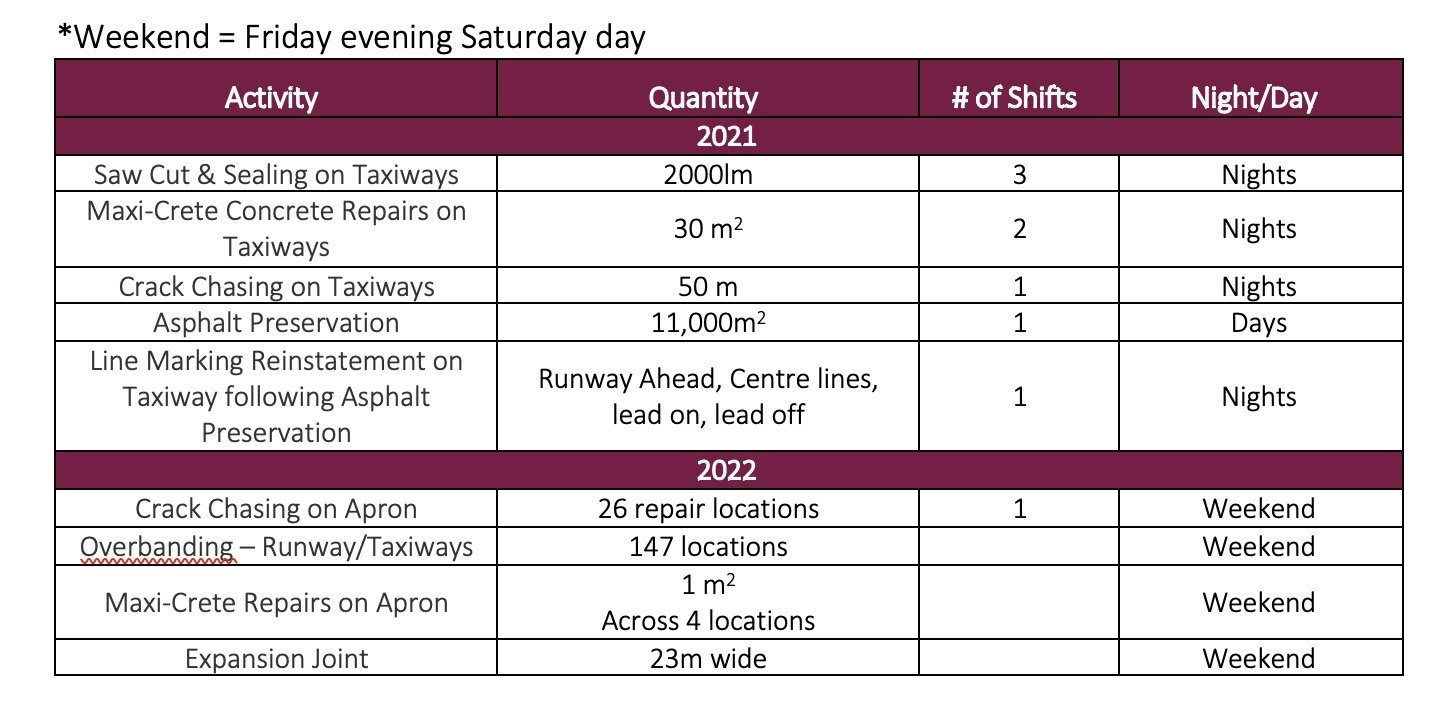

*Weekend = Friday evening Saturday day